GOD'S VENGEANCE - Complete Drivetrain Redux

-

Corner Carver

- Posts: 1166

- Joined: Jun 02, 2006 12:44 AM

- Location: $6,000,000 Man's Hometown

-

Murfinator

- Posts: 1482

- Joined: Sep 07, 2007 1:39 AM

- Location: ZION - 84032

-

Murfinator

- Posts: 1482

- Joined: Sep 07, 2007 1:39 AM

- Location: ZION - 84032

-

Nebraska_e28

- Beamter

- Posts: 9056

- Joined: Apr 13, 2006 11:18 PM

- Location: Council Bluffs, IA

- Contact:

-

Murfinator

- Posts: 1482

- Joined: Sep 07, 2007 1:39 AM

- Location: ZION - 84032

I decided in favor for several reasons:Nebraska_e28 wrote:I've been entertaining the thought of switching to a>a. I'll be curious to see what your IAT is under boost with this setup. Are you going to squeeze a/c in there somehow for those hot Cali summers, or is that getting axed in favor of a performance based car?

1. More condensed and simple packaging

2. Better for 'touring' style of driving

3. Given aforementioned calculations for flow and charge air cooling efficiency the air-to-air will provide sufficient cooling

I'll be datalogging IAT among dozens of other variables.

The A/C compressor was rattling when the car went on jacks 2.5 years ago. Since I rarely used A/C (prefer to roll down the windows) I doubt I'll go through the trouble of re-installing the system. Some of the lines will remain in place, but capped. The compressor, evap canister and condenser have been removed to make room for piping and improve airflow across the intercooler and radiator.

More importantly, with my wife having totalled her Audi TT we've upgraded to an Imola on Imola Red E46 M3 convertible with low miles and tastefully improved by its one owner. The only time I ever turned on the A/C before was when she was accompanying me. The average temperature may be a bit lower where we are living now compared to coastal California as evidenced by the white stuff on the ground.

-

Murfinator

- Posts: 1482

- Joined: Sep 07, 2007 1:39 AM

- Location: ZION - 84032

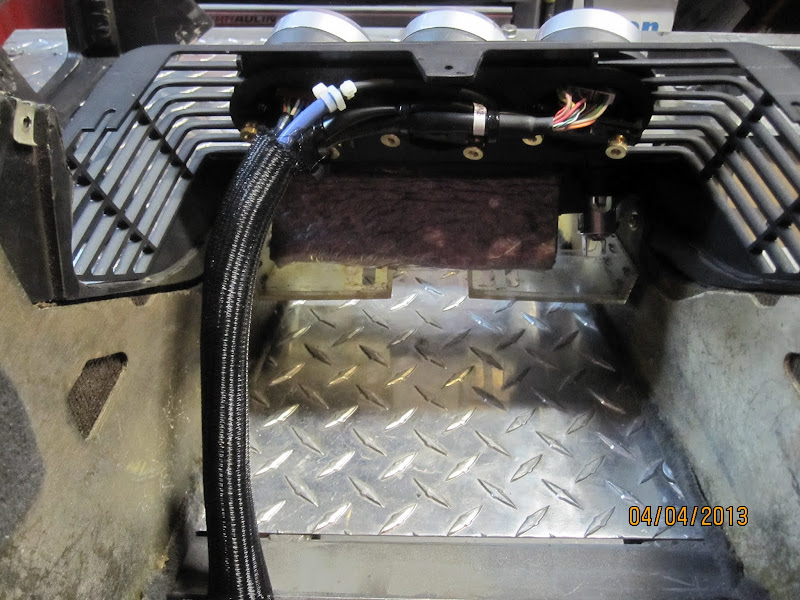

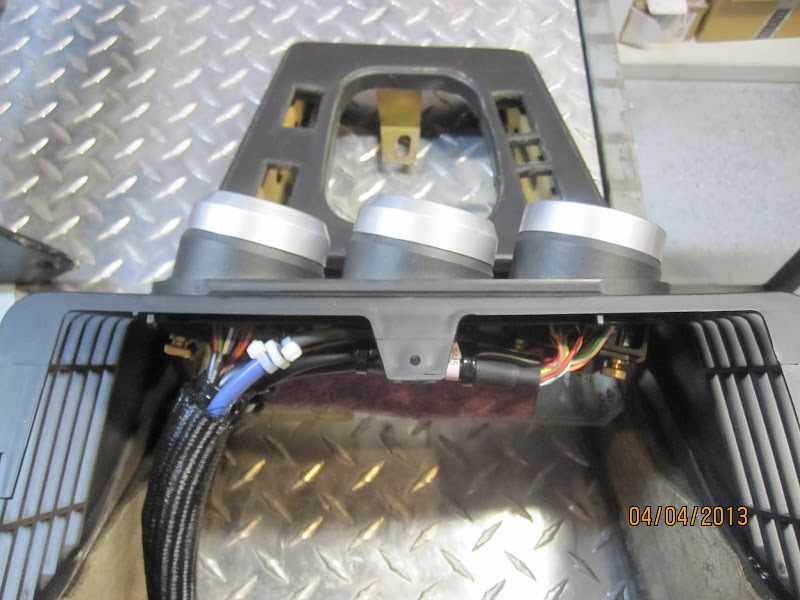

Gauge panel completed. In the panel from left to right are:

AEM Wideband Failsafe (http://www.aemelectronics.com/wideband- ... -gauge-84/) Universal Exhaust Gas Oxygen (UEGO—“you-way-go”) controller with an internal boost sensor, an internal data logger and a full color Organic Light Emitting Diode (OLED) display. It includes technology to activate a failsafe strategy in the event AFR falls outside of a user-defined operating window. If the AFR falls outside of the set operating window, the Wideband FAILSAFE Gauge triggers a user defined output function that can save an engine from catastrophic damage.

In the center and right position are AEM digital serial gauges: "AEM’s Serial Gauge plugs into the company’s Programmable Series 1 and Series 2 EMS and has the ability to read 19 channels simultaneously to provide reference for all outputs, including boost, AFR, EGT, H2O, IAT, knock, volts, RPM, vehicle speed, and more! Since it can read all channels at once, AEM’s Serial Gauge eliminates the need to buy a cluster of gauges, or you can link multiple Serial Gauges together to monitor additional channels or to divide your readouts across a few gauges." (http://www.aemelectronics.com/gauges-26 ... -gauge-33/)

Those of you who have been following this build will recall I purchased the pre-cut plastic panels from Shawn D. several years ago as well as a new grill shell. I was waiting to determine which EMS to use prior to purchasing gauges. With a local AEM-certified shop and chassis dyno specializing in forced induction on imports the choice became that much easier.

[/url]

[/url]

AEM Wideband Failsafe (http://www.aemelectronics.com/wideband- ... -gauge-84/) Universal Exhaust Gas Oxygen (UEGO—“you-way-go”) controller with an internal boost sensor, an internal data logger and a full color Organic Light Emitting Diode (OLED) display. It includes technology to activate a failsafe strategy in the event AFR falls outside of a user-defined operating window. If the AFR falls outside of the set operating window, the Wideband FAILSAFE Gauge triggers a user defined output function that can save an engine from catastrophic damage.

In the center and right position are AEM digital serial gauges: "AEM’s Serial Gauge plugs into the company’s Programmable Series 1 and Series 2 EMS and has the ability to read 19 channels simultaneously to provide reference for all outputs, including boost, AFR, EGT, H2O, IAT, knock, volts, RPM, vehicle speed, and more! Since it can read all channels at once, AEM’s Serial Gauge eliminates the need to buy a cluster of gauges, or you can link multiple Serial Gauges together to monitor additional channels or to divide your readouts across a few gauges." (http://www.aemelectronics.com/gauges-26 ... -gauge-33/)

Those of you who have been following this build will recall I purchased the pre-cut plastic panels from Shawn D. several years ago as well as a new grill shell. I was waiting to determine which EMS to use prior to purchasing gauges. With a local AEM-certified shop and chassis dyno specializing in forced induction on imports the choice became that much easier.

-

Murfinator

- Posts: 1482

- Joined: Sep 07, 2007 1:39 AM

- Location: ZION - 84032

Update: In the past month or so there has been a good deal of progress...

BEGi intercooler installed: I channeled the radiator support, fabricated and welded mounting tabs for the bottom supports. On the top sides I reinforced the existing metal and opened up the holes to accept spring-loaded mounting pins. The two tabs on either side of the core now slide into grooves in the reinforced areas of the radiator support. The pins hold the intercooler secure and allow easy R&R. The bottom mounts have rubber bushings to allow some for limited movement, making it much easier to align the pins at the top. The top mounts don't photograph well with the intercooler in place. The bottom mounts are visible at the bottom of the second pic.

The turbo has been plumbed for water and oil. Oil feed is from the OE 745 filter head and pipe which has been modified with a JIC fitting and stainless braided hose and 90 degree fitting to the center housing. Drain is a -10AN to the oil pan.

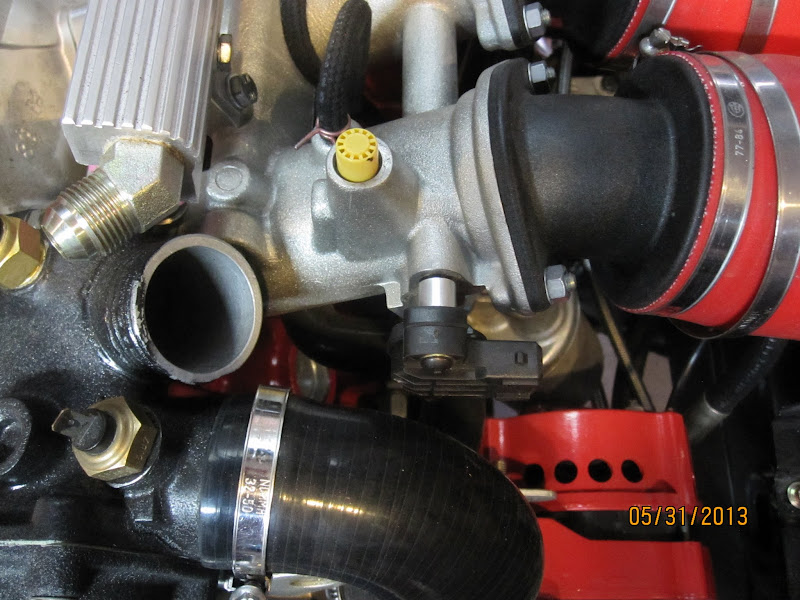

Water input is from the coolant drain at the rear of the block and output is to the t-stat housing. Adapters were required to go from -6 to -8AN.

The need for a potentiometer type TPS due to the AEM EMS and the requirement for one of a much smaller form factor has had me scratching my head for months. The other night I was working on the E46 and decided to remove the TPS and check fitment on the B36 throttles. The bolt spacing is much closer. Yet, when I removed the flange the mounting holes on the E46 TPS and those on the throttle assembly align perfectly. To make it work will require 8mm spacers and removal of a bit of material off the the throttle shaft. Problem solved.

The downpipe was fabricated with 3" stainless. I used one 180, one 45 and a few feet of straight pipe. There is a v-band at the top and bottom with a flex fitting connection to the track pipe.

Still figuring out the packaging on the FPR and battery. Had to downsize the battery to fit the charge pipe from the intercooler to the plenum. The washer tank had to be moved to make room for the catch can, coil packs and intake.

Who say's 275's don't fit an E28?

'Fit' is subjective. Using a fender roller and spacers allows running the wide meats. I'll need the added traction.

Got the fuel pump controller mounted. The rear plate covers the fuel pump while the OE forward pump the sender and return. Had to fabricate the rear cover to rise 1.5" to clear the full-flow 90 degree fitting from the fuel pump. The tank was lowered almost 2".

All the other wiring in the pics feeds:

Studs and spacers: 5mm front, 10mm rear from Turner Motorsports.

BEGi intercooler installed: I channeled the radiator support, fabricated and welded mounting tabs for the bottom supports. On the top sides I reinforced the existing metal and opened up the holes to accept spring-loaded mounting pins. The two tabs on either side of the core now slide into grooves in the reinforced areas of the radiator support. The pins hold the intercooler secure and allow easy R&R. The bottom mounts have rubber bushings to allow some for limited movement, making it much easier to align the pins at the top. The top mounts don't photograph well with the intercooler in place. The bottom mounts are visible at the bottom of the second pic.

The turbo has been plumbed for water and oil. Oil feed is from the OE 745 filter head and pipe which has been modified with a JIC fitting and stainless braided hose and 90 degree fitting to the center housing. Drain is a -10AN to the oil pan.

Water input is from the coolant drain at the rear of the block and output is to the t-stat housing. Adapters were required to go from -6 to -8AN.

The need for a potentiometer type TPS due to the AEM EMS and the requirement for one of a much smaller form factor has had me scratching my head for months. The other night I was working on the E46 and decided to remove the TPS and check fitment on the B36 throttles. The bolt spacing is much closer. Yet, when I removed the flange the mounting holes on the E46 TPS and those on the throttle assembly align perfectly. To make it work will require 8mm spacers and removal of a bit of material off the the throttle shaft. Problem solved.

The downpipe was fabricated with 3" stainless. I used one 180, one 45 and a few feet of straight pipe. There is a v-band at the top and bottom with a flex fitting connection to the track pipe.

Still figuring out the packaging on the FPR and battery. Had to downsize the battery to fit the charge pipe from the intercooler to the plenum. The washer tank had to be moved to make room for the catch can, coil packs and intake.

Who say's 275's don't fit an E28?

'Fit' is subjective. Using a fender roller and spacers allows running the wide meats. I'll need the added traction.

Got the fuel pump controller mounted. The rear plate covers the fuel pump while the OE forward pump the sender and return. Had to fabricate the rear cover to rise 1.5" to clear the full-flow 90 degree fitting from the fuel pump. The tank was lowered almost 2".

All the other wiring in the pics feeds:

Studs and spacers: 5mm front, 10mm rear from Turner Motorsports.

-

Murfinator

- Posts: 1482

- Joined: Sep 07, 2007 1:39 AM

- Location: ZION - 84032

I'm not in a hurry. I've put in an average of 4-8 hours per week on this project. The positive in taking your time is being able to consider each aspect of the build and find/design/build components that work more effectively as a system and bouncing ideas off those who have gone before. Back when I use to waste time watching television I'd be amused by the antics sensationalized on various automotive build shows (e.g. Overhaulin, Boyd Coddington, West Coast Customs, etc...) where a shop with a huge budget and dozens of skilled hands is forced to cut corners and slop together a build in an effort to make a ridiculous deadline.L_N_Love wrote:2 1/2 years. I hope you are getting close to driving that beast.

The 'conventional wisdom' of throwing one of a handful of turbos on a log manifold, adding bigger injectors (maybe) and butt-dynoing an MS tune on the street is definitely not the type of build I had in mind 3 years ago. Overall I'm pleased with the pace and state of the project. With my work schedule I don't expect to fire the motor till October/November.

-

Murfinator

- Posts: 1482

- Joined: Sep 07, 2007 1:39 AM

- Location: ZION - 84032

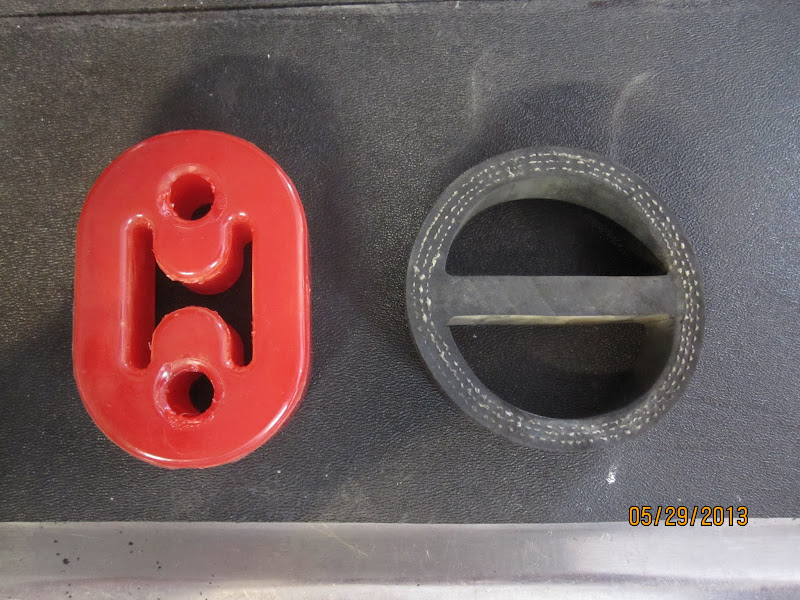

Two years ago I replaced the OE exhaust hangers because they'd dry rotted after 2 years on the car. After another 2 years the replacement pair, which sat in the garage the entire time, were again starting to show signs of wear. After looking into some other options I decided to go with urethane and modify the OE hanger brackets with 8mm studs. I then safety wired the hangers to the brackets to keep them from potentially slipping off. $15 well spent.

Nice work Murf, i wonder how the urethane will cope with the heat, i imagine pretty well with the nice long rod to cool before it reaches the bushing. Totally agree about taking your time and thinking your way through each aspect of the build, no need to rush at all. Soooooo clean, keep up the progress

-

Murfinator

- Posts: 1482

- Joined: Sep 07, 2007 1:39 AM

- Location: ZION - 84032

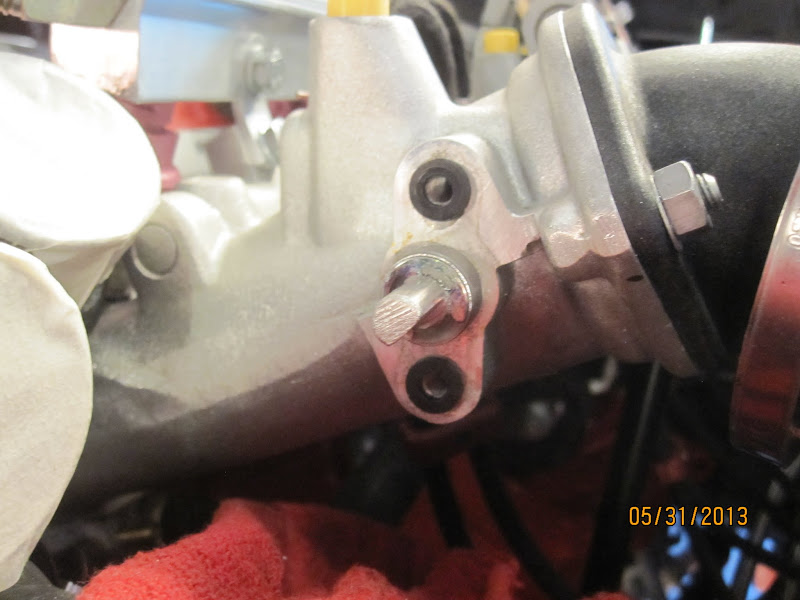

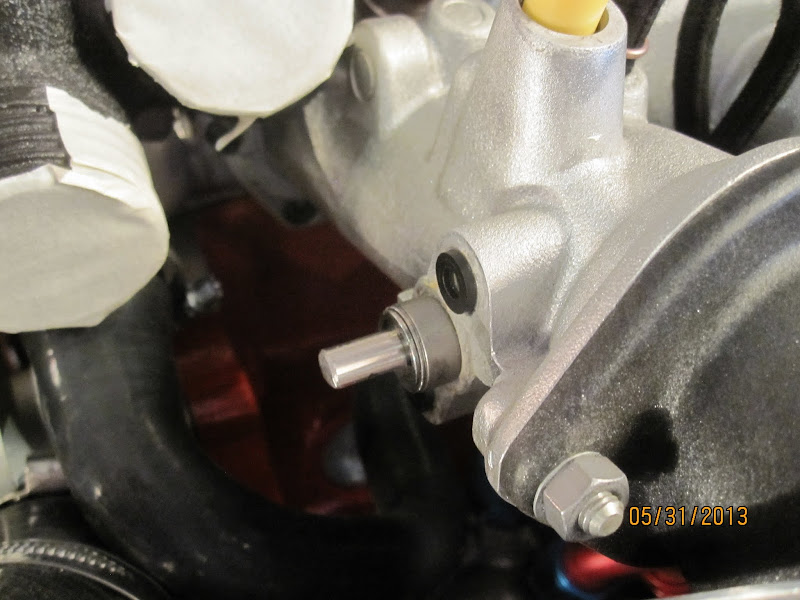

Another hurdle overcome: potentiometer-type TPS for AEM EMS, fuel return / water pump hose clearance.

As stated previously I determined an E46 M3 TPS is both a potentiometer-type TPS with a 3-wire plug-in, a much smaller form factor and also has mounting holes which line up with those which hold the OE flange on a B36 ITB assembly. ~ 3/4" of shaft was removed and the remaining shaft filed to a D-shape. Aluminum 8mm spacers make for a straightforward install.

[/img]

[/img]

As stated previously I determined an E46 M3 TPS is both a potentiometer-type TPS with a 3-wire plug-in, a much smaller form factor and also has mounting holes which line up with those which hold the OE flange on a B36 ITB assembly. ~ 3/4" of shaft was removed and the remaining shaft filed to a D-shape. Aluminum 8mm spacers make for a straightforward install.

-

Murfinator

- Posts: 1482

- Joined: Sep 07, 2007 1:39 AM

- Location: ZION - 84032

Stainless twin-scroll, dual wastegate M30 top-mount exhaust manifold. Internally purged (welds lay nice and flat=no restrictions), TIG welded with T4 divided flange and sensor ports on each equal length primary. I'm very pleased with the results. Total cost was ~ $500 in materials and ~50 hours of measuring, cutting, grinding, welding and fitting.

-

Nebraska_e28

- Beamter

- Posts: 9056

- Joined: Apr 13, 2006 11:18 PM

- Location: Council Bluffs, IA

- Contact:

-

Black Steel

- Posts: 350

- Joined: May 18, 2010 8:19 AM

- Location: Warwickshire, UK

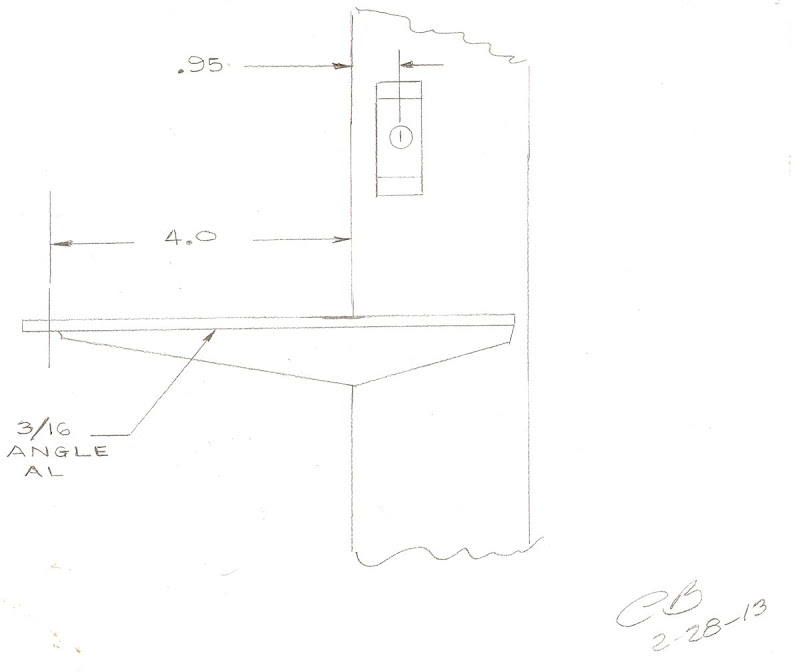

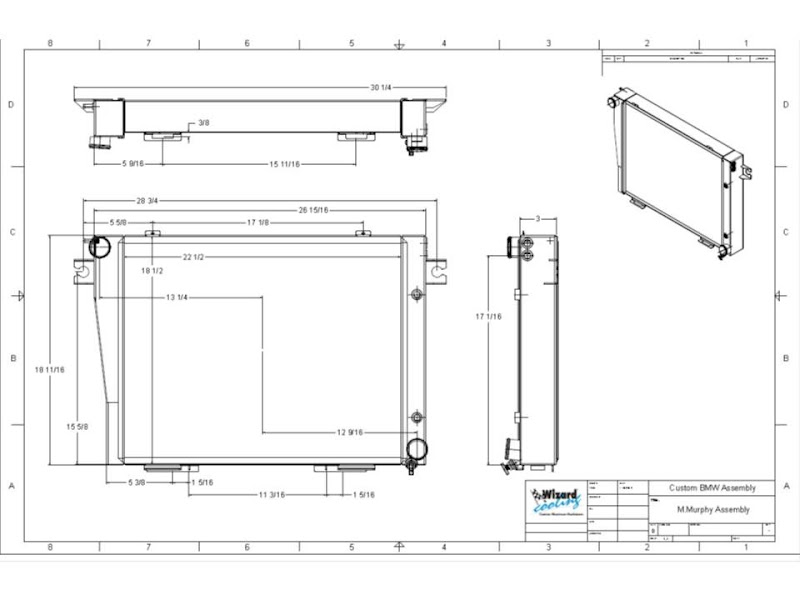

How thick is that radiator Murf? Looks a lot thicker than a standard M535i rad. Is it because one of the rows is for the oil cooling?

Wizards website states one row of 1.5" tubes.

https://wizardcooling.com/products/338- ... iator.aspx

Wizards website states one row of 1.5" tubes.

https://wizardcooling.com/products/338- ... iator.aspx

-

Murfinator

- Posts: 1482

- Joined: Sep 07, 2007 1:39 AM

- Location: ZION - 84032

-

Black Steel

- Posts: 350

- Joined: May 18, 2010 8:19 AM

- Location: Warwickshire, UK

Thanks for the reply. So they made the radiator especially for you then?

It's twice as thick as a standard M535i radiator.

Radiator design is a bit of a black art.

HP/Minute = 42.44 BTU.

My five core is fine for 1200bhp turbo race cars but it's not good for normal fast road driving. It over cools at speeds over 55mph. When I really use the performance over a 15 minute period that mimics track driving with speeds no higher than 100mph with regular hard acceleration it acts like a normal radiator!

Looking at your new radiator it's going to work quite well as a fast road car radiator If your going race it for any length of time (20 plus minutes) you might run into trouble.

It's twice as thick as a standard M535i radiator.

Radiator design is a bit of a black art.

HP/Minute = 42.44 BTU.

My five core is fine for 1200bhp turbo race cars but it's not good for normal fast road driving. It over cools at speeds over 55mph. When I really use the performance over a 15 minute period that mimics track driving with speeds no higher than 100mph with regular hard acceleration it acts like a normal radiator!

Looking at your new radiator it's going to work quite well as a fast road car radiator If your going race it for any length of time (20 plus minutes) you might run into trouble.

-

Murfinator

- Posts: 1482

- Joined: Sep 07, 2007 1:39 AM

- Location: ZION - 84032