Running rich under medium and heavy load

Running rich under medium and heavy load

I just purchased an '85 524td and it runs very rich at full throttle (car behind me almost disappears). The torx adjuster on top of the injection pump was backed out almost all the way when I purchased the car (should be minimum fuel setting, so that's confusing). I checked the vacuum hoses and removed the EGR control stuff so it's out of the way. There are three vacuum hoses going to the injection pump. Manifold reference to the top, vacuum pump to the lower (side) and the barometric pressure going to lower (rear).

I think the adjustment screw on the back of the pump is the main fuel screw? It still has the collar behind the nut, so I don't think it's been messed with. The turbo maxes out at 8psi (low rpm) and 10psi (medium-high rpm). Partial throttle at around 6psi I will get a haze of black smoke, then it gets really bad progressively towards full throttle.

Any ideas on what can be wrong here? The car runs strong and smooth except for at idle, where it has a misfire that gets worse as the engine warms and shakes the car ( I assume injectors need to be serviced). I even drove it home about 400 miles when I purchased it and it returned 32.5 mpg. Thanks.

I think the adjustment screw on the back of the pump is the main fuel screw? It still has the collar behind the nut, so I don't think it's been messed with. The turbo maxes out at 8psi (low rpm) and 10psi (medium-high rpm). Partial throttle at around 6psi I will get a haze of black smoke, then it gets really bad progressively towards full throttle.

Any ideas on what can be wrong here? The car runs strong and smooth except for at idle, where it has a misfire that gets worse as the engine warms and shakes the car ( I assume injectors need to be serviced). I even drove it home about 400 miles when I purchased it and it returned 32.5 mpg. Thanks.

Re: Running rich under medium and heavy load

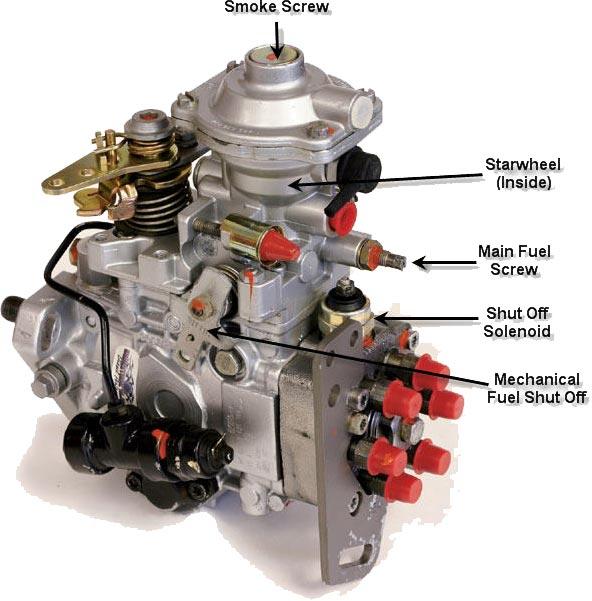

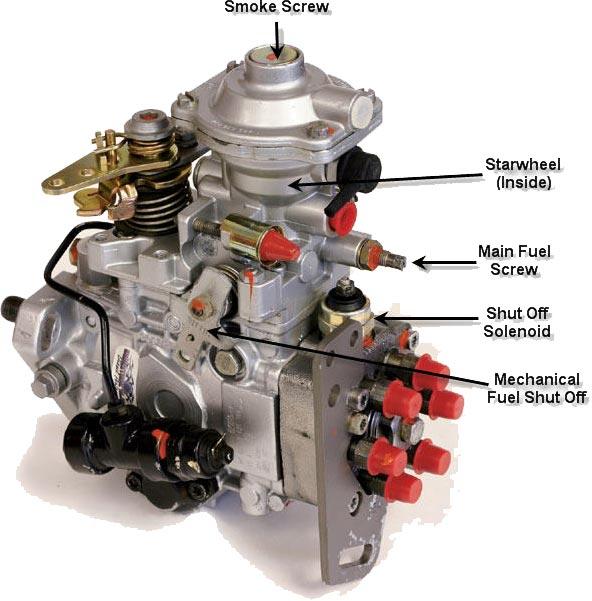

The one on top is the non-boosted fuel adjustment. Dodge guys call that the "smoke screw" because it will make black clouds off-idle if its turned up too much. The full load adjustment is on the side of the pump facing rearward.

If the collar appears intact, I wouldn't fool with the full load adjustment.

Sounds like injector issues but low boost pressure will mess things up too. I have mine set to max out at the top end of factory spec, just shy of 13 psi at full throttle. Yours sounds pretty reasonable though. If the safety wire on the wastegate hasn't been broken you're probably in good shape. Probably worth doing an injector pop test to see if they are leaky and have a reasonable spray pattern.

The US spec BMW has an electronically controlled injector pump. I don't know the inner workings of this system but I know it has something to do with injector timing advance. If that doesn't work you'll have smoke issues since the pump won't advance correctly with engine rpm. My Lincoln doesn't use that pump so its not something I have any experience with. This manual might be of some help though. Ford wrote a ton about that pump, even though they only used it on California models.

http://www.grandmarq.net/gadget73/Ford% ... engine.pdf

On the Lincoln it will light the "check turbo" light, but I'm pretty sure BMW didn't have that bulb. I think you guys got a much scarier "no oil pressure" warning when the turbo over-boosted. If there is diag output from the IP controller to the dash I don't know where it would be.

If the collar appears intact, I wouldn't fool with the full load adjustment.

Sounds like injector issues but low boost pressure will mess things up too. I have mine set to max out at the top end of factory spec, just shy of 13 psi at full throttle. Yours sounds pretty reasonable though. If the safety wire on the wastegate hasn't been broken you're probably in good shape. Probably worth doing an injector pop test to see if they are leaky and have a reasonable spray pattern.

The US spec BMW has an electronically controlled injector pump. I don't know the inner workings of this system but I know it has something to do with injector timing advance. If that doesn't work you'll have smoke issues since the pump won't advance correctly with engine rpm. My Lincoln doesn't use that pump so its not something I have any experience with. This manual might be of some help though. Ford wrote a ton about that pump, even though they only used it on California models.

http://www.grandmarq.net/gadget73/Ford% ... engine.pdf

On the Lincoln it will light the "check turbo" light, but I'm pretty sure BMW didn't have that bulb. I think you guys got a much scarier "no oil pressure" warning when the turbo over-boosted. If there is diag output from the IP controller to the dash I don't know where it would be.

Re: Running rich under medium and heavy load

Thanks for the info. Before I get digging into inspecting the timing, is it worth checking the starwheel/fuel pin? I wouldn't be surprised if the previous owners messed with this stuff to get it to smoke more... It doesn't smoke at all at idle, it's only with increasing load. Also the timing does seems to advance well for cold start (judging by sound), and it starts great. I don't hear any excessive rattle when warm that would make me think the timing was too far advanced when warm, either.

Re: Running rich under medium and heavy load

i'd think lack of timing advance would cause smoke more than too much advance. I think the way that electronic pump works is the controller controls advance based on rpm and load. If the special injector weren't working or the crank speed sensor was bad I would guess that it just gives base timing but I don't know that for sure.

Its possible that if someone jacked up the fuel pin setting its getting too much at part load. Not sure, I've never fooled with that on mine. If you pull the manifold reference line off the boost compensator it should stop moving the pin and that might tell you something. If its still smoking without the extra fuel, its probably not a pump setting. I'd think if someone were going to tinker with the pump though, it would be the full load screw rather than an internal adjustment that would be messed with.

Its possible that if someone jacked up the fuel pin setting its getting too much at part load. Not sure, I've never fooled with that on mine. If you pull the manifold reference line off the boost compensator it should stop moving the pin and that might tell you something. If its still smoking without the extra fuel, its probably not a pump setting. I'd think if someone were going to tinker with the pump though, it would be the full load screw rather than an internal adjustment that would be messed with.

Re: Running rich under medium and heavy load

I tried unplugging what I think were the connectors for the needle lift sensor and advance solenoid, no change in sound from the engine. Also I didn't measure any significant voltage from the solenoid harness connector. For what it's worth, my tach also doesn't work. I realize all of this points to the engine probably running in some kind of limp mode, like you mentioned.

This is what the fuel pin looks like. It seems like there is a witness mark on the deepest side of the pin (most fuel I think?). I will have to try to get it at 180deg out from there and see what it does. I will also try removing the boost reference.

This is what the fuel pin looks like. It seems like there is a witness mark on the deepest side of the pin (most fuel I think?). I will have to try to get it at 180deg out from there and see what it does. I will also try removing the boost reference.

Re: Running rich under medium and heavy load

I reinstalled the fuel pin with the shallow side towards the front of the engine (I see that's where the ball pushes against the pin. That seemed to reduce smoke a significant amount. I then backed off the starwheel about 1 turn at a time. It smoked progressively less each turn. I got to about 5 turns out and it's just a light smoke now at medium and heavy throttle. It does seem to have lost some power all around, but it's hard to say for sure.

Under investigation, my needle lift sensor is showing no continuity across the terminals, so it must be dead. I have a spare set of injectors that has a seemingly good sensor on it, so I'm going to get those rebuilt. The engine speed sensor is reaching the ECU connector OK (about 3VAC at idle), but tach is not working. I don't seem to be getting any tach signal out of the ECU when measured at the C101 connector.

I'm only reading about 100mV at the advance solenoid harness connector, even when revving, so that doesn't seem to be getting any signal from the computer. I don't know if that's because the lift sensor is dead, or the computer is dead. The computer is getting power, but I can't find any evidence of it doing anything between the lack of signal to the advance solenoid and tachometer. Also, the Injection light on the check control is not on, to no fault of the bulb.

Under investigation, my needle lift sensor is showing no continuity across the terminals, so it must be dead. I have a spare set of injectors that has a seemingly good sensor on it, so I'm going to get those rebuilt. The engine speed sensor is reaching the ECU connector OK (about 3VAC at idle), but tach is not working. I don't seem to be getting any tach signal out of the ECU when measured at the C101 connector.

I'm only reading about 100mV at the advance solenoid harness connector, even when revving, so that doesn't seem to be getting any signal from the computer. I don't know if that's because the lift sensor is dead, or the computer is dead. The computer is getting power, but I can't find any evidence of it doing anything between the lack of signal to the advance solenoid and tachometer. Also, the Injection light on the check control is not on, to no fault of the bulb.

Re: Running rich under medium and heavy load

Open coil on the lift sensor injector should mess with the ECM control, but I'd expect a warning light about that. Maybe the ECM died. Does it do the lamp prove-out? Not just as simple as a bad fuse or power relay?

any chance your meter reads in frequency? That would give you a more solid idea of what the crank sensor output is doing but if its got output its probably working as expected.

pic of the fuel pin didn't load. I've honestly never been into that area on mine.

did some closer reading in one of the Ford manuals about the VP-20 pump. It says "To change injection pump timing the computer controls the cycling of a fuel control solenoid in the injection pump. The solenoid varies the amount of fuel pressure available to the advance piston by providing an additional bleed whenever it is open."

By that it sounds like maybe the timing would work straight mechanical if that solenoid is not powered and not stuck open, and powering it only retards the timing. The non-electronic pump runs advance purely on fuel pressure, more pressure = more engine speed = more advance, essentially like flyweights in a distributor. The initial timing on the two pumps is not the same, so its possible the advance curve is not the same either. I would expect that the electronic one would have more mechanical advance so the computer has more operational range since it can only pull timing out. But thats just a guess.

any chance your meter reads in frequency? That would give you a more solid idea of what the crank sensor output is doing but if its got output its probably working as expected.

pic of the fuel pin didn't load. I've honestly never been into that area on mine.

did some closer reading in one of the Ford manuals about the VP-20 pump. It says "To change injection pump timing the computer controls the cycling of a fuel control solenoid in the injection pump. The solenoid varies the amount of fuel pressure available to the advance piston by providing an additional bleed whenever it is open."

By that it sounds like maybe the timing would work straight mechanical if that solenoid is not powered and not stuck open, and powering it only retards the timing. The non-electronic pump runs advance purely on fuel pressure, more pressure = more engine speed = more advance, essentially like flyweights in a distributor. The initial timing on the two pumps is not the same, so its possible the advance curve is not the same either. I would expect that the electronic one would have more mechanical advance so the computer has more operational range since it can only pull timing out. But thats just a guess.

Re: Running rich under medium and heavy load

The lamp prove-out is not working when the ignition is turned on. According to the ETM, there is no fuse between that bulb and the ECU. Between that and the tach not working, it seems to me like the computer is not working. I will probably turn to buy a spare on ebay if no-one offers one for sale here.

My meter does read frequency, and I was getting about 100-150 hz at idle, and seemed to increase proportionally with revving.

I'm also confused by the timing solenoid. If it is a controlled bleed from the advance piston, and the valve is normally closed (what the manual shows), then the failsafe mode is full advance. That seems backwards from what it should be logically. I think more damage can be done with overly-advanced timing than overly retarded. If it was OK to run with the engine so far advanced all of the time, what would the point of retarding the timing be? Could be simply NOx emissions I suppose. I'm going to give the solenoid 12v while the engine is running and see how that affects noise/rpm.

My meter does read frequency, and I was getting about 100-150 hz at idle, and seemed to increase proportionally with revving.

I'm also confused by the timing solenoid. If it is a controlled bleed from the advance piston, and the valve is normally closed (what the manual shows), then the failsafe mode is full advance. That seems backwards from what it should be logically. I think more damage can be done with overly-advanced timing than overly retarded. If it was OK to run with the engine so far advanced all of the time, what would the point of retarding the timing be? Could be simply NOx emissions I suppose. I'm going to give the solenoid 12v while the engine is running and see how that affects noise/rpm.

Re: Running rich under medium and heavy load

I opened up the ECU and found tons of water damage. Actually, it's probably mouse piss damage, judging by the nest on top of it. It honestly smells horrible. So I'm in the market for a new ECU.

Re: Running rich under medium and heavy load

It won't be full advance exactly, it will just be a set amount of advance based on engine rpm like the non-electronic pump is. My guess is that its designed or set in such a way that it can't advance to the point of being able to cause damage, but maybe I'm wrong on that. Initial timing with the electronic pump is less, but I have no idea what the internal spring or port is like between the two. I'd guess that the spring on the electronic one brings in the advance quicker, but possibly the initial timing setting doesn't actually allow it to advance to the point where damage can happen. Would be nice if the only thing you had to do in order to convert an electronic to a non-electronic pump is swap the advance spring. You'd need an internal part number breakdown to see precisely what items are different between the pumps. The info must exist for rebuild purposes but no idea where or if you can get it.

For the fuse I was thinking more of one between power and the ECU, not between the lamp and the ECU. If its full of mouse piss though, thats probably what ails it.

Does the tach signal pass through the ECU, or just tee off to it? How do the Euro versions run the tach since they don't have an ECU? Just thinking maybe if its possible to make the pump non-electronic in a reasonable manner that could be a better solution than trying to find the controller.

For the fuse I was thinking more of one between power and the ECU, not between the lamp and the ECU. If its full of mouse piss though, thats probably what ails it.

Does the tach signal pass through the ECU, or just tee off to it? How do the Euro versions run the tach since they don't have an ECU? Just thinking maybe if its possible to make the pump non-electronic in a reasonable manner that could be a better solution than trying to find the controller.

Re: Running rich under medium and heavy load

I'd guess you're right about the timing.gadget73 wrote:It won't be full advance exactly, it will just be a set amount of advance based on engine rpm like the non-electronic pump is. My guess is that its designed or set in such a way that it can't advance to the point of being able to cause damage, but maybe I'm wrong on that. Initial timing with the electronic pump is less, but I have no idea what the internal spring or port is like between the two. I'd guess that the spring on the electronic one brings in the advance quicker, but possibly the initial timing setting doesn't actually allow it to advance to the point where damage can happen. Would be nice if the only thing you had to do in order to convert an electronic to a non-electronic pump is swap the advance spring. You'd need an internal part number breakdown to see precisely what items are different between the pumps. The info must exist for rebuild purposes but no idea where or if you can get it.

For the fuse I was thinking more of one between power and the ECU, not between the lamp and the ECU. If its full of mouse piss though, thats probably what ails it.

Does the tach signal pass through the ECU, or just tee off to it? How do the Euro versions run the tach since they don't have an ECU? Just thinking maybe if its possible to make the pump non-electronic in a reasonable manner that could be a better solution than trying to find the controller.

The fuse for the ECU is fine, I find good power and ground at the ECU connector.

The original ECU was definitely toast, corroded joints, burned out sections. I found a replacement on ebay but I still have no tach or injection light. I still need to test if there's any signal going to the timing solenoid but right now it seems like this ECU is also bad.

Re: Running rich under medium and heavy load

looks like tach output comes from pin 21 on the timing control unit. Fault indicator comes from pin 12 and looks to be a constant hot / switched ground setup. It shares the + feed with the seat belt and water in fuel lights. If those work then the fault has to be something control side of that light. I guess if you wanted to verify wiring integrity between the cluster and the controller you could jump 12 to ground and see if the injector fault light comes on. Maybe use a test light just in case something goes bad.

It does also look like tach signal goes to the service interval thing. A problem there could make the tach not work.

It does also look like tach signal goes to the service interval thing. A problem there could make the tach not work.